A careful and ever-growing company is particularly concerned about standards and legislation. That's why for us, at SPL INDUSTRIES, achieving quality and safety certifications is definitely not an option, but rather a "must".

And here comes, thanks to the hard work of our professionals, the acquisition in October 2015 of the first ISO 9001:2008 certification related to quality management system. This allowed us to increase the quality level in all aspects, thanks to well-studied controls aimed to guarantee the maximum quality in supplies and a functional and efficient service to the client.

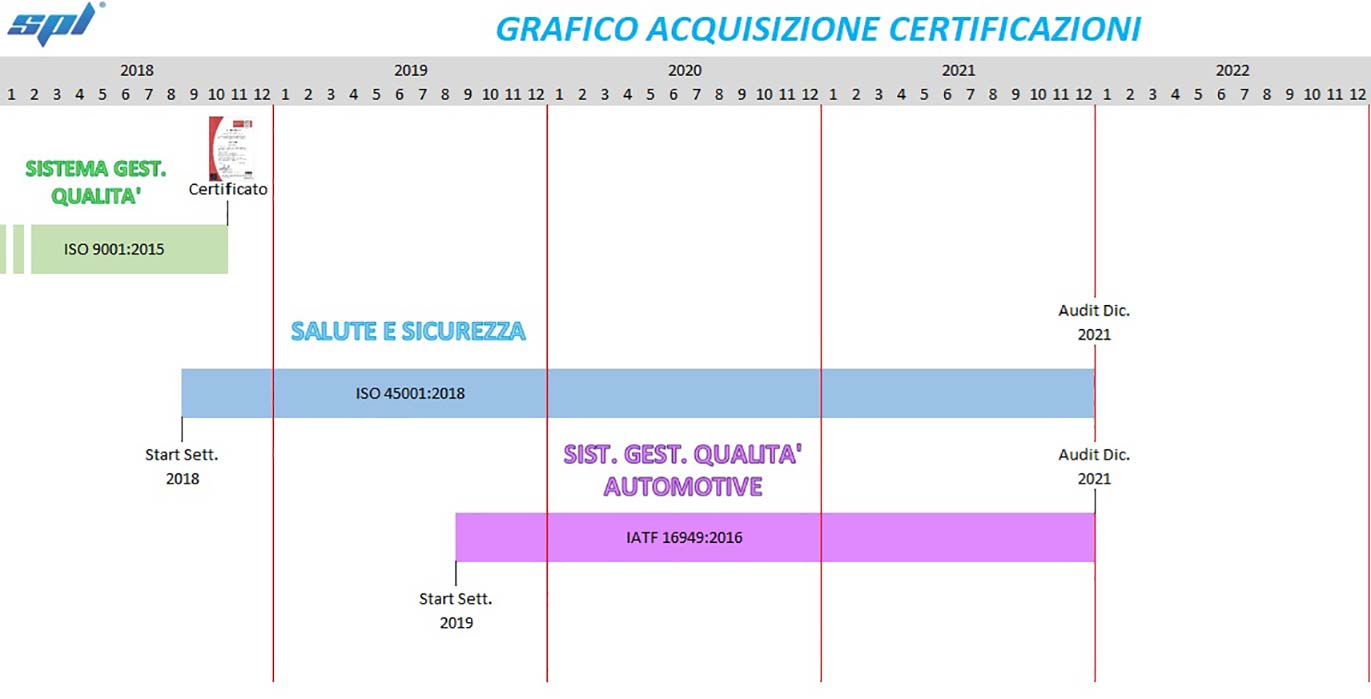

Given the excellent results, in October 2018 we worked to achieve the ISO 9001:2015 update.

We are equally concerned about Health and safety, in fact, since September 2018, we have been working to acquire the ISO 45001 certification, with the aim to complete the process within December 2020.

Such legislation replaces the current OHSAS 18001 and has the purpose to implement an organizational system which may allow to prevent accidents and occupational diseases.

It includes some specific requirements such as: identify work-related risks, develop a SSL politics and related goals, implement preventive controls, evaluate and improve the SSL indexes and the workers' involvement.

Recently, we at SPL INDUSTRIES decided to insert in our “certification planning” also the IATF 16949:2016, related to the management quality system for the Automotive industry.

Such legislation allows an important “upgrade” on systems and tools for process control, in addition to a greater focus on customer experience in terms of quality and delivery.

More specifically, the legislation focuses on some requirements. Among them:

identification of tech-spechs and critical characteristics;

approach to risk analysis (FMEA);

advanced quality planning (APQP);

approval process of new products (PPAP);

realization of control plans, statistical process controls, measuring system analysis (MSA);

predictive and preventive maintenance, compliance of laboratories, management of non-compliant products, process and product audits, data analysis and problem solving, impact of corrective operations and creation of emergency plans.

Given the complexity and importance of such certification, the way to get is not small thing, but we at SPL INDUSTRIES are very confident and on September 2019 we are already going to start the process to achieve it within December 2021.