The body-in-white department carries out the last stage of the production cycle prior to shipment. When required, the molded parts are further processed by welding the small items designed, such as screws, dice, cages, so that to deliver a finished product that will be then assembled in our customers' facilities, together with the other vehicle body components.

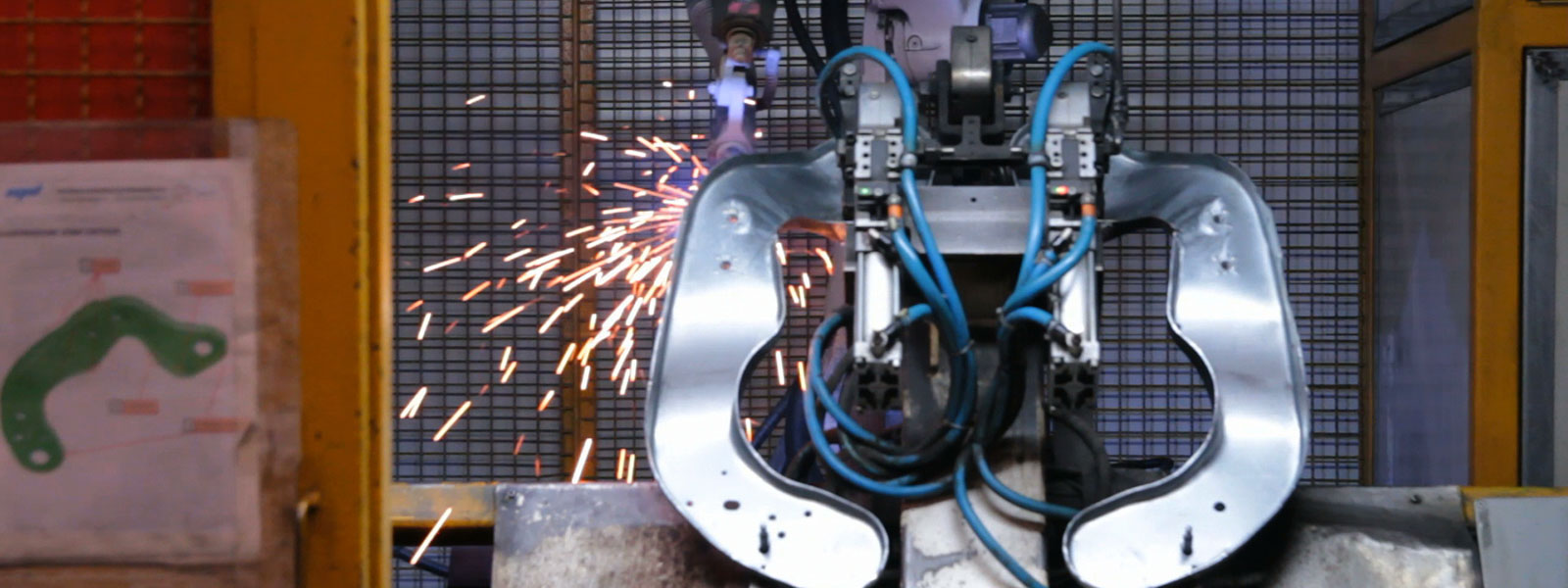

The body-in-white unit consists of two column welding/punching machines of 125 and 250 Kw and of a Panasonic welding robotic island with tilting table. The leak tests on welded components are carried out with special torque wrenches and, in case of important parts like suspensions, the check shall be extended to the semi-finished molded product; for this very purpose, a specific area has been set up within the body-in-white department, where highly qualified personnel carries out the reinforced ex GP12 control.

Our machines

Welding system

· Robotic welding system (Panasonic) with tilting table